MODEL:

Grinding and polishing machine, modular system that can be configured on customer production requirements, dimensioned for working on medium to big size products, with heavy payload handling system and high performance units.

Suitable to achive a big stock removal on the diameter in order to repair from defects and or create and homogeous surface with target roughness.

STO - Heavy Grinding for Big size products

Applications

For model STO

Features

Round products

MODEL

Workable products

Workable dimensioms

Diameters

Length

Tools used

Working conditions

STO Technical

Carachteristics

Alternatives to STO

This model is offered in different configurations taccording to production volumes

Possible applications are:

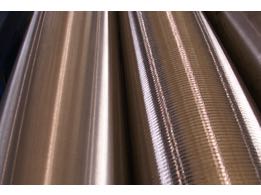

- Welded tubes - Cosmetic finishing, satin or mirror polish.

- Seamless pipes - after piercing/extrusion process for defects

removal and roughness improvement

- Cylinders sizing to dimension.

- Rolls polishing

- Bars - grinding of extra material, defects removal and

roughness improvement.

- Hard crhomed products.

HANDLING The machine is offered with dedicated handling system to work automatically from bundle to bundle, and dimensioned according to the products to be processed.

AUTOMATION The working cycle is fully automatic, managed and monitored through PLC System, the machine further set automatically, this function is operated by the main panel with the simple input of diameter value and can be handled thtough recipes where each single paramether can be differently customized.

FURTHER ADVANCED Functions adre availanle throught a HMI - with GRAPHIC INTERFACE integrated into the cabin and positioned in Front of each finishing unit through, this will help the operator to supervise the production cycle and to operate localised fine tuning of the machine during working operations.

STO is provided with an ADVANCED CONTROL SYSTEM of THE WORKING PRESSURE, adjustable independently for each unit according to the required performances and tools used.

STO - Available with different transport system and workable range.

Tubes, pipes and bars, bundle to bundle

From 20 to 220 mm - From 60 to 350 mm (Other on demand)

Length from 3 up to 14 mt (according to transport system)

Tools used: Grinding belts or polishing wheels.

Dry with dust collector or wet with coolant liquid filtration system.